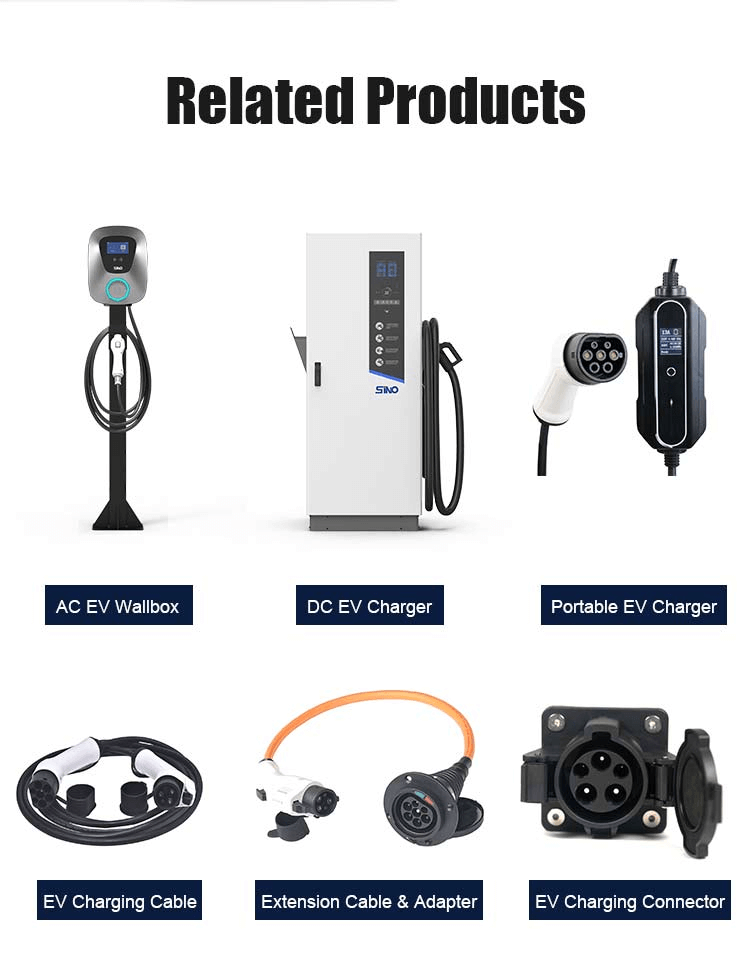

Products

Fast, Reliable, Everywhere

Solutions

Efficient, Innovative EV Charging Solutions.

News

We are committed to the innovation and application of EV charging.

A spilt ev charger is a modern solution for electric vehicle charging that divides the charging system into two main parts: the control unit and the charging cable. This separation allows for greater flexibility and adaptability in various installation environments. Unlike traditional integrated charging stations, the split design enhances the ease of installation and operational efficiency by keeping the control unit separate from the cable.

Control Unit: The control unit is the central component of the spilt ev charger. It typically includes a power conversion module, a charging control system, and a communication interface. This unit converts alternating current (AC) into direct current (DC) and manages parameters during the charging process, such as current, voltage, and charging power. It also communicates with the electric vehicle to ensure the charging process is safe and reliable.

Charging Cable: The charging cable connects to the control unit via a connector. It is designed to be highly flexible and adaptable, allowing adjustment of its position and length as needed. The cable transmits power to the vehicle’s charging interface and directly supplies energy to the vehicle’s battery.

Power Supply: The control unit of the Split EV Charger receives AC from the power grid. It converts this AC into DC through an internal power conversion module. This involves rectification and filtering to ensure the output power is stable and safe.

Vehicle Communication: The control unit and the vehicle exchange data via communication protocols (such as PLC or CAN). The control unit coordinates with the vehicle’s charging management system to set charging parameters (like current and voltage) and monitor the charging status. It also checks the state of the vehicle’s battery to prevent damage during charging.

Charging Management: During charging, the control unit adjusts the output power based on the vehicle’s battery needs. It monitors safety aspects such as overheating, overcurrent, or voltage anomalies, and takes necessary measures to prevent faults or accidents.

Safety Protection: Split ev chargers generally feature multiple safety protections, such as overcurrent, overvoltage, and over-temperature protection, to ensure safe operation. Additionally, the control unit may include ground fault protection to mitigate electrical hazards.

Maintenance Convenience: The modular design of spilt ev charger makes maintenance and component replacement easier. If the control unit or charging cable malfunctions, the faulty part can be replaced without changing the entire charger. This design also supports upgrades and expansions to accommodate evolving charging needs.

Integrated Design: Traditional charging stations typically use an integrated design, combining all key components into a single unit. This includes the charging control unit, power conversion module, and charging cable. While this design is straightforward, it may present challenges in installation and maintenance.

Traditional charging stations, often referred to as AC or DC chargers, have been foundational to electric vehicle infrastructure. They can be categorized as:

Charging Control: Traditional charging stations typically include a charging control system that monitors and adjusts charging parameters (like current and voltage). This system communicates with the vehicle to ensure that the charging process meets the vehicle’s requirements.

Installation and Maintenance: The integration of all components into a single unit can make the installation and maintenance of traditional charging stations more complex. This is particularly true for DC fast chargers, which may have higher installation and maintenance costs.

The spilt ev charger separates the charging system into two components: the control unit and the charging cable. The control unit is typically installed in a fixed location, such as on a wall or bracket, while the charging cable can be positioned and adjusted as needed.

This split design makes installation more flexible, particularly in environments with limited space or where cable management is important. For instance, the control unit can be placed near a power source, while the cable can extend to the vehicle’s parking area. This flexibility simplifies installation and reduces the need for major modifications to existing infrastructure.

When installing a spilt ev charger, it is essential to ensure a stable connection between the control unit and the cable, meeting electrical safety standards. Power capacity and circuit protection considerations are also necessary to ensure proper operation.

Traditional charging stations integrate all components into a single device. This includes the power conversion module, charging control system, and charging cable. All components being in one unit means that installation must ensure the stability and electrical connections of the entire device.

Installation of traditional charging stations may require more space since the device must be fixed in place and considerations for cooling and safety must be addressed. Additionally, high-power charging stations might need dedicated power distribution systems and additional wiring.

| Cost Investment | Split EV Charger | Traditional Charging Station |

| Initial Investment | Lower initial investment: The control unit and charging cable of a split EV charger are separate, allowing flexible configuration and procurement based on needs. Flexible configuration: This design allows users to choose different specifications for the control unit and cable according to actual needs, reducing initial costs. | Higher initial investment: Traditional charging stations usually integrate all components, including the power conversion module, charging control system, and cable.This integration leads to higher initial procurement and installation costs. Particularly for DC fast chargers, the equipment cost is high, leading to significant initial investment. Fixed configuration: The integrated design limits configuration flexibility, requiring users to purchase a device that meets all needs at once, potentially leading to higher initial investment. |

| Operating Costs | Lower operating costs: Users can operate and maintain the control unit and charging cable independently, reducing downtime and maintenance costs. Energy efficiency: Split EV chargers typically offer higher charging efficiency, better adapting to vehicle charging needs and reducing energy consumption and costs. | Higher operating costs: The integrated design of traditional charging stations can lead to higher operating costs, especially when maintenance or repairs are needed. If a fault occurs, the entire station might need to be taken offline for repairs, potentially affecting operational efficiency. Energy consumption: Traditional charging stations may have lower charging efficiency compared to modern split chargers, leading to higher energy costs over time |

| Maintenance Costs | Lower maintenance costs: The modular design of split chargers makes maintenance and component replacement easier. If the control unit or cable fails, the faulty part can be replaced individually without changing the entire unit. This reduces maintenance costs and equipment downtime. Simplified maintenance: Users can perform maintenance and upgrades based on needs, reducing associated costs and time. | Higher maintenance costs: With all components integrated into one device, maintenance of traditional charging stations may require disassembly and reinstallation of the entire unit, leading to higher costs. Potential upgrade costs: Traditional charging stations might need significant upgrades or replacements with technological advancements, increasing long-term maintenance and upgrade costs. |

| Upgrade Costs | Technological adaptability: The modular design allows for flexible upgrades and expansions, avoiding the need for complete replacement of outdated equipment. This design helps adapt to technological advancements, extending the device’s lifespan and enhancing long-term economic benefits. | Device lifespan: Complete replacement or large-scale upgrades of traditional charging stations can incur additional expenses. Traditional stations may require significant upgrades as technology evolves, impacting long-term cost-effectiveness. |

Summary

Split EV Chargers generally offer superior performance in terms of initial investment, operating costs, maintenance costs, and long-term economic benefits. Their modular design provides flexibility and reduces long-term costs, making them a cost-effective choice for various applications.

Traditional charging stations, with their integrated design and higher initial investment, may have lower cost-effectiveness in long-term use. Although still a reliable solution, their higher maintenance and operating costs may affect overall economic benefits.

Charging Rate: Spilt ev charger can support high power output depending on the control unit’s design and the specifications of the charging cable. They support multiple charging standards, including AC and DC. Split chargers that support DC fast charging can provide faster charging speeds, suitable for high-demand scenarios. In high-power configurations, they can offer charging rates similar to DC fast chargers.

Charging Efficiency: Split chargers typically provide higher efficiency because their design optimizes the power transfer process. With separate control units and charging cables, these devices manage current and voltage more effectively, reducing energy loss. The separation also helps manage heat dissipation, minimizing the impact of overheating on efficiency.

Charging Rate: The charging rate of traditional charging stations depends on their design type:

AC Charging Stations: Generally have lower efficiency due to multiple conversion steps: from AC to DC and through the vehicle’s onboard charger. These steps can result in energy loss.

DC Fast Charging Stations: Usually have higher efficiency because the conversion from AC to DC happens within the charging station, reducing losses during the charging process.

Selecting the appropriate charging solution based on specific needs and application scenarios ensures that charging requirements are met while optimizing economic benefits and operational convenience.

Choose spilt ev charger: When flexibility, efficient charging, and lower initial investment are desired. Suitable for environments with limited space, high power or fast charging needs, and where lower long-term maintenance costs and easy expansion are important.

Choose Traditional Charging Station: When mature technology, stable charging service, and solutions suited to fixed environments are required. Ideal for public charging networks, high-density charging, and high-power demands, with a budget that allows for higher initial investment and long-term maintenance costs.

Split ev chargers offer flexibility and cost-effectiveness, making them an excellent choice for many modern applications. Traditional charging stations, with their mature technology and fast charging capability, remain a reliable solution for high-demand environments.

As a leading provider of innovative energy solutions, we are dedicated to helping you make these choices and implement the most effective charging infrastructure based on your needs. Our expertise in energy solutions ensures that you receive a tailored approach that combines the latest technology with practical considerations to deliver the best performance and value.